Winders

Menu

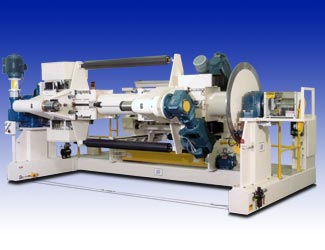

New Era manufactures a wide variety of winding equipment for web converting applications. Our systems range from single position units to multi-spindle winders, can handle web widths from .5″ wide up to 20 feet wide and range in line speeds from 3000 fpm down to a few inches per minute. Our custom designs are implemented for your exact web materials and process constraints, providing you with a purpose built winding solution. New Era has multiple patents associated with winding, including an automatic, on-the-fly, zero fold-over winder capable of cutting extremely tough web materials.

- Automatic transfers at up to 3000 FPM

- Shafted or Shaft-less chucking of cores

- Multiple knife styles and geometries available

- Fully automatic tension control and sidelay

- Zero fold-over core starts

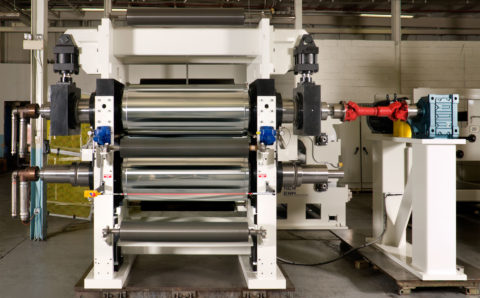

- Automatic transfers at up to 500 FPM

- Lay-on roll and gap winding features available

- Shafted or Shaft-less chucking of cores

- Shafted or Shaft-less chucking of cores

- Lay-on roll and gap winding features available

- Cantilevered or dual side support

- Fully automatic tension control and sidelay

- Shafted or Shaft-less chucking of cores

- Cantilevered or dual side support

- Fully automatic tension control and sidelay

- Lay-on roll and gap winding features available

Downloadable Brochures in PDF Format

Downloadable Brochures in PDF Format