Beacon Falls, CT (August 10, 2018) . . . New Era Converting Machinery has built an “industry best” reputation on delivering state-of-the-art converting machinery that continually exceeds performance expectations. This success depends in part on using the very best after-market components on these production lines.

New Era offers single, multi-position and turreted unwind/rewind options for their coating and laminating lines, and when this equipment calls for air shafts and safety chucks, New Era relies on Goldenrod Corporation’s expertise in multi-bladder shaft and safety chuck technology.

“We have had great success utilizing the Goldenrod safety chucks and shafts”, says Paul Lembo, Executive Vice President of New Era. “In addition to handling some of our more challenging, custom chucking applications, Goldenrods’ line of standard products are widely used on our unwinds and winders.” The multi-bladder shafts are designed to New Era’s customers’ exact specifications. New Era has also incorporated Goldenrod’s New Model 926 Safety Chuck design.

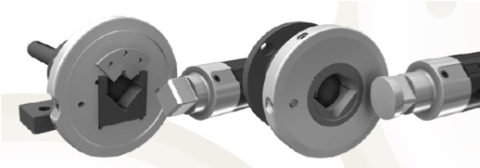

Conventional safety chucks have a closing ring made from cast steel which creates metal dusting and premature wear. The new Goldenrod Model 926 has a forged steel closing ring and a machined steel cam that ensures positive, guaranteed closing and longer service life. The Chuck has a redundant push button on the left and right side of the closing ring making installations simple with easy operator access. The redundant lock system is perfect for turrets.

The Model 926 is an upgrade to the older Model 927 Safety Chuck, but has the same mounting dimensions for those customers that want to upgrade. It is available in light, medium and heavy-duty foot and flange mount profiles.

Socket inserts are replaceable and are designed to ensure long shaft journal life. They are available in either “V” square shape for easy loading or the popular “VO” square/round shapes for smooth and quiet rotation at high speeds. The chucks can be disassembled easily with a hex wrench.

New Era’s converting machinery is among the most state-of-the-art, complex, and high performing equipment of its type in the industry, and Goldenrod is their preferred choice for chucks and shafts. Goldenrod’s products are capable of maximizing the efficiency and productivity of New Era’s industry-leading equipment, taking the high-end machinery to the next level and allowing them to function at their peak capacity. Contact Goldenrod today to find out how to do the same with your own process and equipment!

ABOUT GOLDENROD CORPORATION

Since 1986, Goldenrod has been designing and manufacturing industry-leading differential winding shafts, multiple bladder air shafts, lightweight aluminum and carbon fiber shafts, reel spools, chucks, and safety chucks for the paper, plastics, film, and foil converting industries.

For more information about Goldenrod products, call toll-free 1-800 GOLD-ROD (465-3763) or (203) 723-4400, or visit the company’s web site at www.goldenrodcorp.com.

Downloadable Brochures in PDF Format

Downloadable Brochures in PDF Format