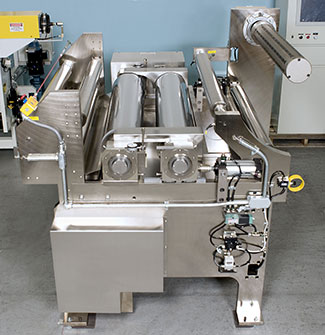

New Era manufactures a wide variety of web coating equipment, including gravure, offset gravure, differential offset gravure, slot die, reverse roll, knife over roll (KOR), dip and squeeze, mayer rod, spray, slide and five roll coaters to name a few. Every coater we build is purpose designed for our customers’ exact process conditions. Our coater designs range from standard construction with manual adjustment to fully automatic, closed loop systems controlled real time by online thickness gauging systems. These closed loop systems can control coater pump speeds, roll speeds and gap profiles utilizing servo positioned gap controls. Our designs cover a wide range of line speeds (from inches per minute to upwards of 3000 feet per minute) and web widths (a few inches wide up to 20 feet wide). New Era fabricates coating machinery for water based, solvent and hot melt processes and we have the ability to trial most coatings on our pilot line.

- Direct gravure, reverse gravure, offset gravure

- Pre-metered coating application

- Sleeved backing rolls for quick rubber roll changes

- Enclosed Applicator or Doctor Blade and Pan

- Hot Melt, Aqueous or Solvent based Slot Die

- Pre-metered coating application

- Slot die over roll or tensioned web

- Wide speed range with good thickness accuracy

- Nip or pan fed coating delivery

- Wide coating thickness and viscosity ranges

- Good method for changing coating laydown rates

- Pre-metered coating application

- Used to apply thin coatings

- Typically designed with 4, 5 or 6 rolls

- Good speed range, 3000 FPM or more

- Wide coating thickness and viscosity range

- Can be designed for a dedicated coating method or flexible, allowing a variety of coating methods

- Various cartridge and modular designs available

- Tool-less module insertion and removal

- Useful where total product thickness is important

- Can be run at ambient or with hot melt coatings

- Works well with non-uniform substrates

- Adjustable edge dams for coating width control

- Slot die, reverse roll, gravure, knife over rolls and transfer roll coaters can all run hot melt coatings

- Wide speed range and coating thickness range

- Hot melt delivery systems from a range of vendors

- Hybrid type coating applicators

- Purpose designed coaters based on a customers application requirements

- Can be designed as dedicated or modular

Downloadable Brochures in PDF Format

Downloadable Brochures in PDF Format