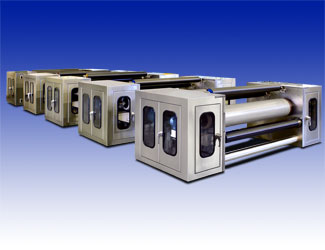

Cleanroom Equipment

- Fully integrated equipment lines

- Coating, laminating, embossing and web handling

- Specially designed for ISO Class 5 - 8

- Production scale and pilot lines

- Clean splicing and cutting technologies

- Auto roll loading to reduce operator interaction

- All operating components outside the process

- Shafted or shaft less chucking options

- Clean room models of all our standard coaters

- Close fitting enclosures for improved cleanliness

- Purpose designed fluid delivery systems

- Closed loop coater controls available

- Specially designed nip sets for ISO Class 5 - 8

- Simple combining nips up to high pressure nips

- Precision gap or pressure control

- Single and multi ply substrate configurations

- Fully automatic available to traverse airlock

- Core or OD handling features

- Core loading/jumbo unloading for winders

- Core unloading/jumbo loading for unwinds

- Accumulators for zero speed splicing/transfers

- Air turns and web flips utilizing HEPA filtered air

- Vacuum pull roll tension isolation stations

- Wide variety of ancillary web handling sections

- Clean transfer and cutting technologies

- Auto roll unloading to reduce operator interaction

- Shafted or shaft less chucking options

- Patented zero fold-over winding technology

Downloadable Brochures in PDF Format

Downloadable Brochures in PDF Format