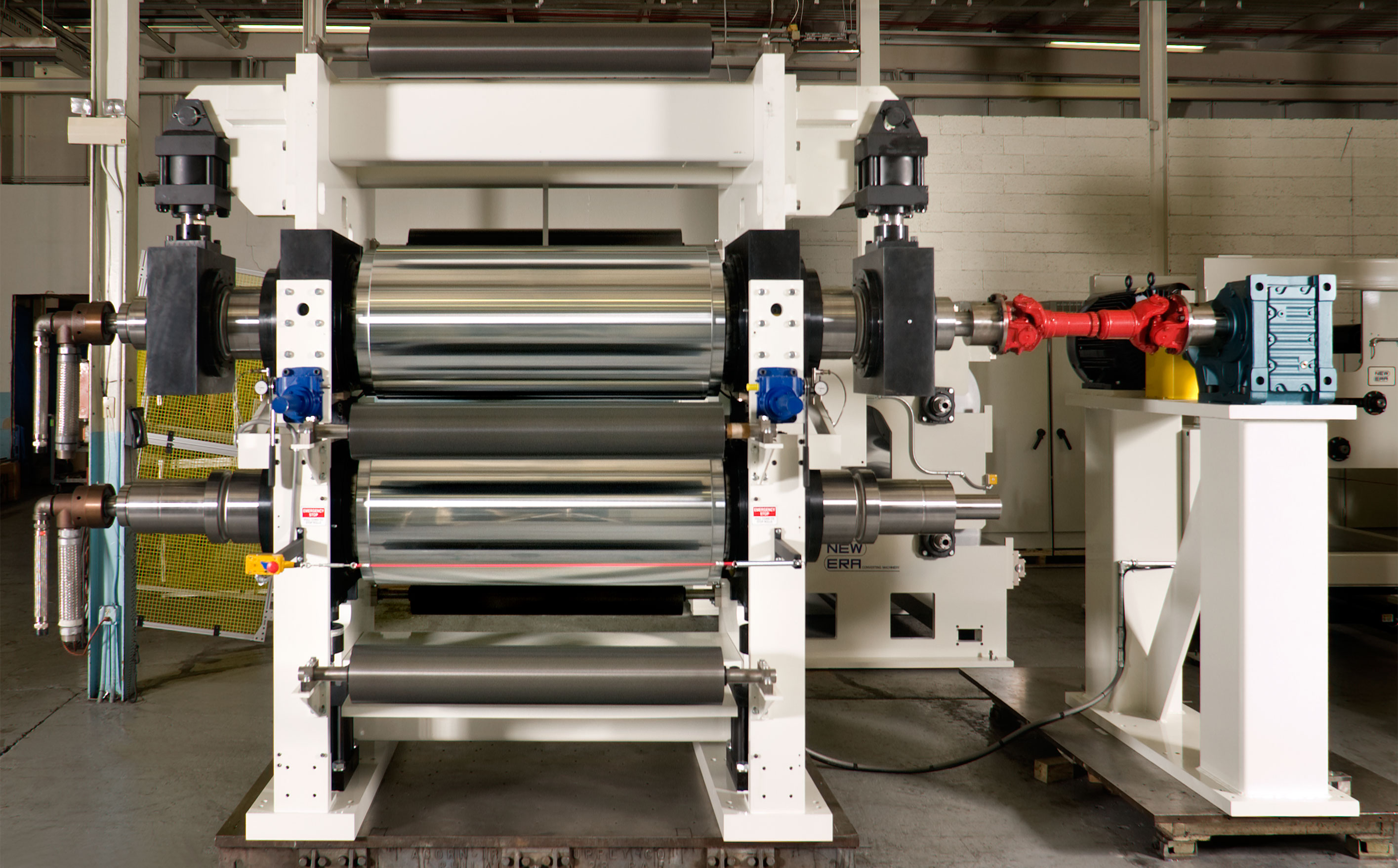

Laminators, Embossers, and Calenders

- Precision gap or pressure control

- Sleeved rubber rolls for quick changes

- Heating or cooling capability

- Preheating by contact, IR, hot air or other

- Load cell nip pressure readout for process control

- Modular designs for embossing pattern changes

- Thermal calculations for heating and cooling

- Split cap bearing housings for ease of roll changes

- Roll bending, crowned rollers or skewing available

- Closed loop process controls from thickness gauge

- Thermal calculations for heating and cooling

- Servo positioned gap controls

- Combination systems featuring nip sets

- Cartridge or modular systems

- Machine direction travel to meet process needs

- Dolores eos qui ratione voluptatem sequi nesciunt

- Specially designed nip sets for ISO Class 5 - 8

- All operating components outside the process

- Non-corrosive & durable materials of construction

- FDA approved materials when required

Downloadable Brochures in PDF Format

Downloadable Brochures in PDF Format