The following is the second part in a series of 5 blogs that will go through a presentation given by New Era Converting Machinery’s Bob Pasquale at 2018 AIMCAL R2R Europe Conference. The presentation is titled “Selecting an Unwind and Unwind Splicer System.”

Part 1 offered an overview and introduction to the blog series, as well as the holding of the roll while unwinding. Part 2 will discuss tension control of the unwinding material. Part 3 will go through the guiding of the web as it exits the unwind and how the expiring roll’s web will be spliced to the beginning of the new roll’s web. Part 4 will continue with a consideration of how the expiring roll’s web will be cut and the number of unwind positions. Part 5 will wrap the series up, finishing with a comparison of roll to roll versus continuous unwinding, and then offer a brief Conclusion.

TENSION CONTROL OF THE UNWINDING MATERIAL

The two major areas to address regarding unwind tension control are:

- The need for constant tension control

- The method of generating the tension

The Need for Constant Tension Control

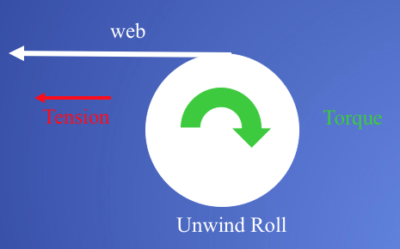

On a center unwind web tension is applied by using a device to impart a drag on the shaft/spindle that holds the web roll. This drag force results in a torque on the unwind roll.

The torque is related to web tension through the following formula:

Torque = Force X Radius

Where:

- Force = the web tension

- Radius = the radius of the unwinding roll

Therefore, in order to keep the web tension constant, the torque needs to be adjusted as the roll size changes.

Non-Constant Tension System

A system where no adjustments are made to the drag force, resulting in a system where the web tension varies as the unwind roll diameter changes.

Advantages:

- Minimal cost

- Minimal maintenance

Disadvantages:

- Web tension varies as the unwind roll diameter changes

Constant Tension System:

A system where adjustments are made to the drag force as the unwind roll diameter changes, resulting in a constant web tension. This can be with no web feedback such as sonic sensor to measure the unwind roll diameter and adjust the drag force accordingly or with web feedback such as a force transducer or dancer to automatically maintain constant tension.

Advantages:

- Allows for the web to be delivered to the process under constant tension

Disadvantages:

- Costly

- Requires extra space

- Higher maintenance

The Method of Generating the Tension

One must decide on what type of device should be used to generate the web tension. Typically this is done through the use of either a brake or a motor/drive set.

Braked System

Advantages:

- Less costly to purchase, install and operate

- Easier to operate

- Minimal maintenance

- Pneumatic brakes are excellent for use in a hazardous environment

Disadvantages:

- Limited total tension range

- May be difficult to use at low tensions

- Not good for use with damaged rolls

- May not work well during roll acceleration where the acceleration force is greater than the required web tension

- Not good for applications where the web roll needs to be accelerated prior to unwinding

Motor/Drive System

Advantages:

- Greater total tension range

- Good for use at low tensions

- Good for use with damaged rolls

- Works well during roll acceleration where the required acceleration force is greater than the web tension

- Good for applications where the web roll needs to be accelerated prior to unwinding

Disadvantages:

- More costly to purchase and install, especially in a hazardous environment

- Higher maintenance

- Not good a low speeds, where reflected inertia is an issue

###

*That concludes part 2 of our 5 part blog series, “Selecting an Unwind and Unwind Splicer System” – click here to read part 3, or go back and read part 1 here!

Downloadable Brochures in PDF Format

Downloadable Brochures in PDF Format