Unwinds

Menu

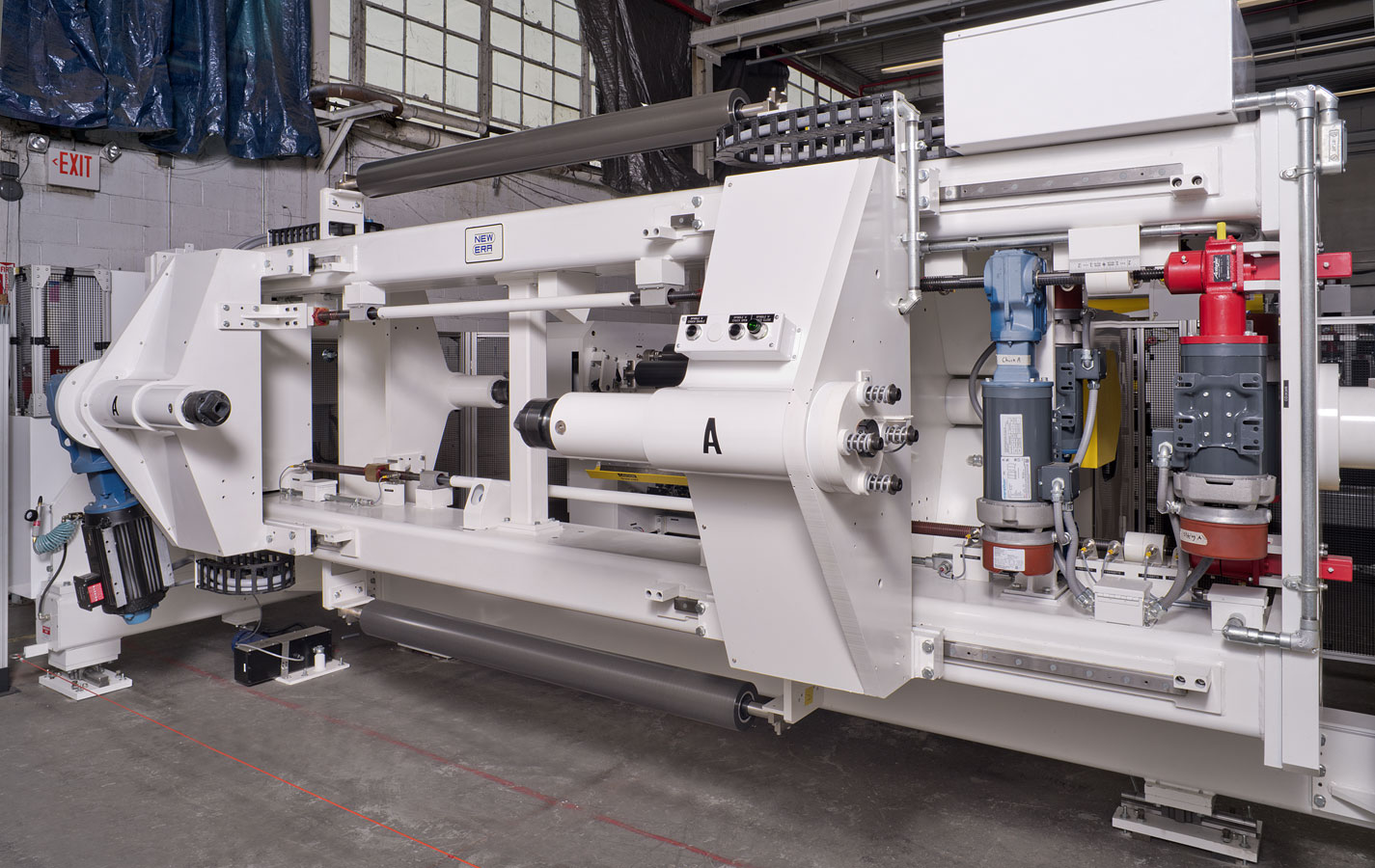

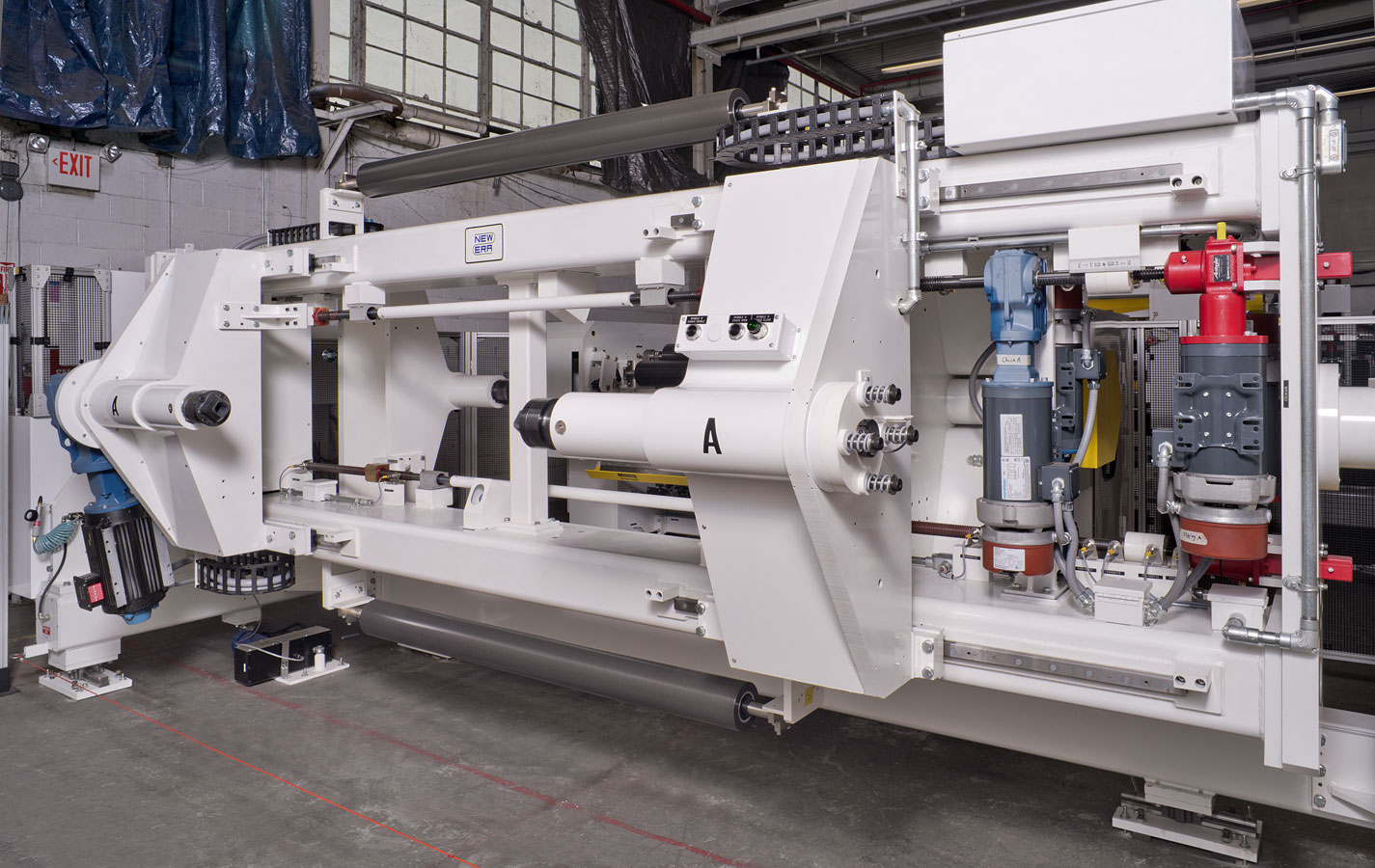

New Era manufactures a wide variety of unwinding equipment for web converting applications. Our systems range from single position units to multi-spindle unwinds, can handle web widths from .5″ wide up to 20 feet wide and range in line speeds from 3000 fpm down to a few inches per minute. Our designs are custom implemented for your exact web materials and process constraints, providing you with a purpose built unwinding solution. New Era has multiple patents associated with unwinding, including an automatic on-the-fly butt splicing system.

- Automatic splicing at up to 3000 FPM

- Shafted or Shaft-less chucking of cores

- Multiple knife styles and geometries available

- Fully automatic tension control and sidelay

- Provides a lap-less (near butt) splice at full line speed

- No accumulators are required with this technology

- Can cut and splice a wide range of materials

- Driven or braked spindles available

- Shafted or Shaft-less chucking of cores

- Cantilevered or dual side support

- Fully automatic tension control and sidelay

- Driven or braked spindles available

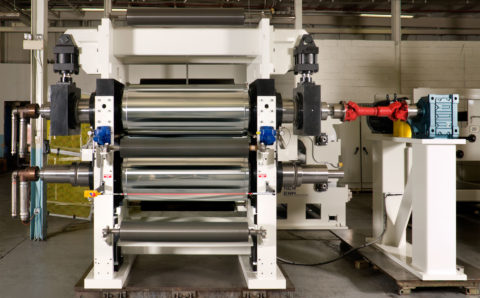

- Shafted or Shaft-less chucking of cores

- Cantilevered or dual side support

- Fully automatic tension control and sidelay

- Provides a taped splice for each of the two webs

- No accumulators or slowing down the process

- Fully automatic splicing

- Can cut and splice a wide range of materials

Downloadable Brochures in PDF Format

Downloadable Brochures in PDF Format