The following is the final in a series of 3 blogs that will go through a white paper written by New Era Converting Machinery’s Bob Pasquale and Tom Lombardo. The white paper is titled “Design Considerations in Solvent Vs. Water Based Coating Equipment.”

Part 1 offered an overview of the entire paper and what to expect in coming blogs. Part 2 discussed how to design equipment to address solvent flammability and operator health. Part 3 finishes with design considerations for emissions, what drying equipment differentiation there is between the two, and how to resist corrosion, as well as a short conclusion.

—–

Part 3: Design Considerations for Emissions, Drying Equipment Differentiation, and Resisting Corrosion

DESIGN OF EQUIPMENT FOR EMISSIONS:

One of the important features in the design of a solvent coating system is the capture and abatement of the solvent vapors/gases that are released. As discussed above, ventilation equipment and/or coater enclosures are utilized to capture the solvent vapors/gases at the coater area. Once they are captured, the solvent vapor/gases that are present in the air stream that is exhausted from the ventilation equipment and/or coater enclosure needs to be dealt with either through recovery or destruction. Systems are available to allow for the separation of the solvent vapors/gases from the air stream so that they can be collected either for destruction or reuse. Other systems are available to allow for the destruction of the vapors/gases present in the air stream (incinerators).

Associated with the solvent based coating system is a dryer for the removal of the solvents. It is typical that the air stream from the coater ventilation equipment or enclosure is combined with that of the dryer and fed to a common collection or destruction unit. In fact, since the amount of solvent vapors/gases present in the air stream that exits the coater area is typically very low, it is quite common to feed this exhaust stream directly to the dryer. This allows for the amount of solvent vapor/gas in the air stream to be increased so that the size of the abatement equipment, which is based on the volume of air, can be minimized.

With typical water base coatings, since there are no environmentally harmful vapors/gases being released, there is no need for the use of abatement equipment.

DRYING EQUIPMENT FOR SOLVENT BASED VS WATER BASED COATINGS:

As indicated earlier, the design differences for a solvent based versus water based drying system is a very large topic of discussion which deserves its own paper. However, there are several major differences that we can briefly touch on.

As previously mentioned, solvents typically take much less energy to remove. This allows for lower drying temperatures, shorter dryers and/or faster speeds when solvent coating.

A solvent based dryer is required to include explosion relief panels.

Special design considerations need to be applied to any hardware that comes in direct contact with the solvent vapors/gases. This includes the use of spark proof fans.

Prior to operation, a solvent based dryer needs to go through a purge cycle to make sure that no residual solvents are present.

The solvent dryer’s air handling equipment needs to be designed to assure that the levels of solvent in the air never go above a certain percentage. Depending on the design of the system, this may require the inclusion of solvent level monitoring equipment (LFL monitors).

The air stream exhausted from the solvent dryer cannot be released to the environment. It instead needs to be fed to an abatement system such as a recovery unit or a destruction unit.

Because of the presence of water in the air stream, care must be taken regarding the internal design of a dryer for water based coatings to prevent corrosion, with stainless steel often being used.

EQUIPMENT DESIGN FOR CORROSION RESISTANCE:

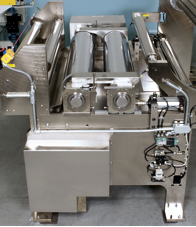

When designing equipment for use with solvent based or water based coatings, one needs to address the detrimental effects of exposure to the coatings.

Certain solvents attack the mild steel that is commonly used to fabricate the coating equipment. Based on the solvent, care needs to be taken in selecting either special coatings to apply to the equipment or special materials to fabricate the equipment from.

When using water based coatings, it is important to address the concern of corrosion due to oxidation. As above this can be done either through coatings such as chrome, etc. applied to the mild steel or by fabricating the components from other materials such as stainless steel. As an alternative, the equipment can be provided with a mild steel frame that is clad with stainless steel on the surfaces that are exposed to the coating.

CONCLUSION:

In conclusion, there are many factors that need to be considered when designing a system to handle solvent based coatings. Care must be taken to assure that fires/explosions will not occur, that the operators will not be exposed to the solvent vapors/gases and that the vapors/gases are properly captured so that they are not released into the environment. In addition the coater should be designed to prevent excessive corrosion that may occur from contact with the coating.

BIOGRAPHY:

Bob Pasquale is one of the founders and principals of New Era Converting Machinery, where he serves as President. He holds a degree in Mechanical Engineering from Stevens Institute of Technology and has worked in the web converting industry since 1985. He is the holder of several patents in the industry. Bob can be reached at bob.pasquale@neweraconverting.com.

Tom Lombardo is Vice President of Engineering at New Era Converting Machinery. He has an extensive background in the design and operation of web converting equipment, having started in the industry in 1978. He is associated with several patents in the industry. Tom can be reached at tom.lombardo@neweraconverting.com.

REFERENCES:

www.exmanlift.com

National Fire Protection Association’s National Electric Code handbook, 13th Addition

###

That concludes our blog series. If you missed them, please read part 1 and part 2!

Downloadable Brochures in PDF Format

Downloadable Brochures in PDF Format