The following is the third and final part of a series of 3 blogs that will go through a white paper written by New Era Converting Machinery’s Bob Pasquale. The white paper is titled “Design Considerations in Unwind Tension Control Systems.”

Part 1 offered an overview of the entire paper and what to expect in coming blogs. Part 2 went through sizing a braking system and the various types of braking systems on the market. Part 3 will wrap the series up with types of braking systems controls and offer a brief conclusion.

—–

Part 3: Types of Braking Systems Controls & Conclusion

TYPES OF BRAKING SYSTEM CONTROLS:

As critical as the selection and sizing of the braking system is, the selection and design of the system used to control it is just as important. The systems used to control these can be broken down into two major categories, open loop systems and closed loop systems.

In the open loop system, the braking force is set and adjusted independent of any feedback from the web or unwinding roll. As an example, a pneumatic brake can be used with a manual regulator and gauge. In this set up the web tension is adjusted using the regulator to vary the air pressure to the brake and therefore the brake’s force. In this arrangement there is no feedback that tells the operator what the web tension is. Therefore, the only way to obtain a desired web tension is by calculating the required brake torque based on roll diameter and web width and then adjusting the regulator based on information from the brake’s torque chart. Additionally, since the web tension is directly related to the roll’s diameter, the operator must continuously adjust the pressure to maintain a constant tension. The same is true for open loop systems using electric brakes or motor/drives, where the power to the device needs to be set based on calculations and continuously adjusted as the diameter changes.

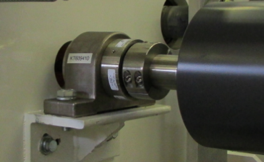

To address the need for adjustments based on changes in the roll’s diameter, an unwind can be equipped with a device that continuously monitors the diameter. This device provides an output signal that the braking system uses to automatically adjust for the changing diameter. There are several different methods employed for this including non-contact devices such as sonic sensors and photo-eyes and contact type systems such as rider rolls/wheels. The feedback from the device provides a signal that equates to the diameter, allowing for the braking control system to automatic adjust the air pressure to the brake or power to the motor to compensate for the changes. However, though these devices provide a means for measuring the roll’s diameter, they do not provide a way for measuring/monitoring the web tension and therefore have no way of confirming if the settings are correct.

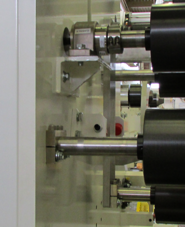

By using a tension sensing roll a true closed loop system can be achieved. In this set up the web wraps a roll mounted on force transducers that are used to sense the web tension and provide an output signal that is used to automatically control the braking system. In a properly set up system, the operator simply needs to input a web tension value, with the system automatically adjusting to compensate for changes in roll diameter through true tension feedback. One drawback of this system is the inability to set the braking system based on the initial diameter of the unwind roll prior to starting to run. However, this can easily be addressed by adding one of the devices as described in the previous paragraph, allowing for the roll’s diameter to be measured and the braking system automatically adjusted accordingly.

Though tension sensing rolls as described above are an excellent way to control an unwind braking system, there are certain applications were they can be problematic. Because of the limited travel of a force transducer system, they are not well suited for applications with sudden changes in web tension. As an example, a severely out-of-round or out-of-balance roll may result in sudden tension changes. Another example is the tension upset that might be seen by the web when an automatic transfer is made on a continuous operation unwind. In these cases, the force transducer’s limited travel may preclude it from being able to appropriately react which could result in tension transients being reflected to other parts of the processing line.

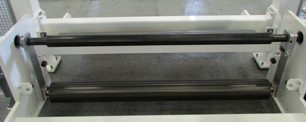

To address the issues outlined above, it is common to equip the unwind with a dancer system for controlling the unwind braking system. In these cases an assembly is provided that features a roll (or series of rolls) that is allowed to move, typically by being mounted on pivoting arms or slides. This dancer assembly is then interconnected with a loading device that applies a force to the web through the roll. Also provided with the dancer assembly is a device that senses the dancer assembly’s position. A typical control scheme for a dancer system is to have the force of the loading system automatically adjusted to provide the required web tension, with the position feedback device used to control the unwind braking system to maintain the dancer’s position. The movement of the dancer assembly allows the system to absorb any major unwind tension upsets.

A dancer assembly, as described above, has no way of directly monitoring the web tension; nor does it have the ability to monitor the diameter of an unwinding roll. To address these issues it is common to have an unwind control system that features a sensing device such as a photo-eye or sonic sensor to determine the initial roll’s diameter, a dancer to control the web tension and a force transducer roll to monitor the web tension and even trip the dancer assembly accordingly.

CONCLUSION:

As outlined above, a wide variety of systems are available for applying and controlling unwind braking systems. It is important that the braking and control systems selected meet all of the unwinding requirements. It is also important that the hardware selected is appropriately sized so that proper braking is provided over the entire range of operation of the unwind.

BIOGRAPHY:

Bob Pasquale is one of the founders and principals of New Era Converting Machinery, where he serves as President. He holds a degree in Mechanical Engineering from Stevens Institute of Technology and has worked in the web converting industry since 1985. He is the holder of several patents in the industry. He can be contacted at:

New Era Converting Machinery

P.O. Box 377

Hawthorne, NJ 07507

(P) 201-670-4848

(F) 201-670-8867

Bob.pasquale@neweraconverting.com

REFERENCES:

Packaging Digest, Using an AC Motor As A Brake For Web Unwind Applications, March 1, 2004

Cohen, Edward and Gutoff, Edgar, Coating and Drying Defects, John Wiley & Sons, 1995

Shepherd, Frank, Modern Coating Technology Systems, Emap Maclaren Ltd, 1995

###

*Thank you for reading! We hope you learned something. Please contact New Era with any comments or questions about this white paper. And, if you missed them, click here to read Part 1 or click here to read Part 2!*

Downloadable Brochures in PDF Format

Downloadable Brochures in PDF Format