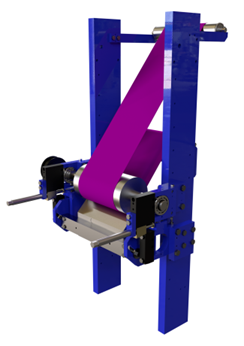

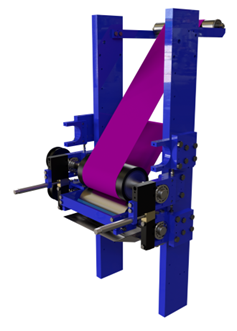

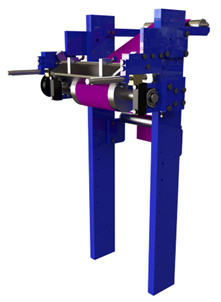

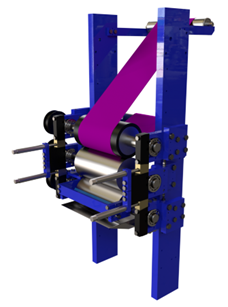

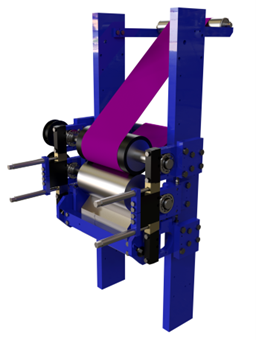

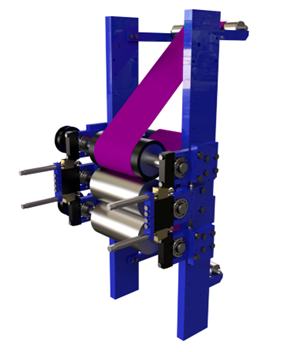

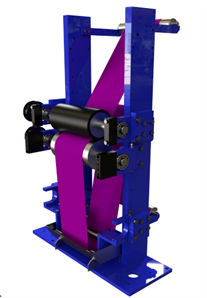

New Era is completing assembly of one of its portable coating lines (PCL) which will be available for sale on a first come, first serve basis and available for shipment in December of 2024. The PCL is designed to meet an end users ever-changing requirements in R&D, product development and product feasibility. The system offers a multitude of coating applications methods (all of which are available on the unit currently in production) and is designed with true “table-top” portability and ease of installation in mind.

The PCL can handle web widths up to 6″ and speeds up to 50 FPM. The unit in production is capable of the following coating methods:

The following process parameters apply:

- Unwind and winder roll diameters of up to 13″ on 3″ diameter cores.

- Solvent and water based coating capability (fully enclosed coater for use with solvents)

- Hot air dryer with adjustable air temperature (single zone)

- Dryer and coater exhaust fan

- Touchscreen controls

- Minimal installation requirements:

- Caster mounted for portability

- Fits through a 30″ wide x 80″ doorway

- Runs on 110V power and 80 PSI air

- Plugs into standard wall outlets

- Single point compressed air connection

- Single point exhaust ducting

Don’t miss out on this opportunity to take the next step in your process development with a coating line ready to ship in a matter of weeks.

Downloadable Brochures in PDF Format

Downloadable Brochures in PDF Format