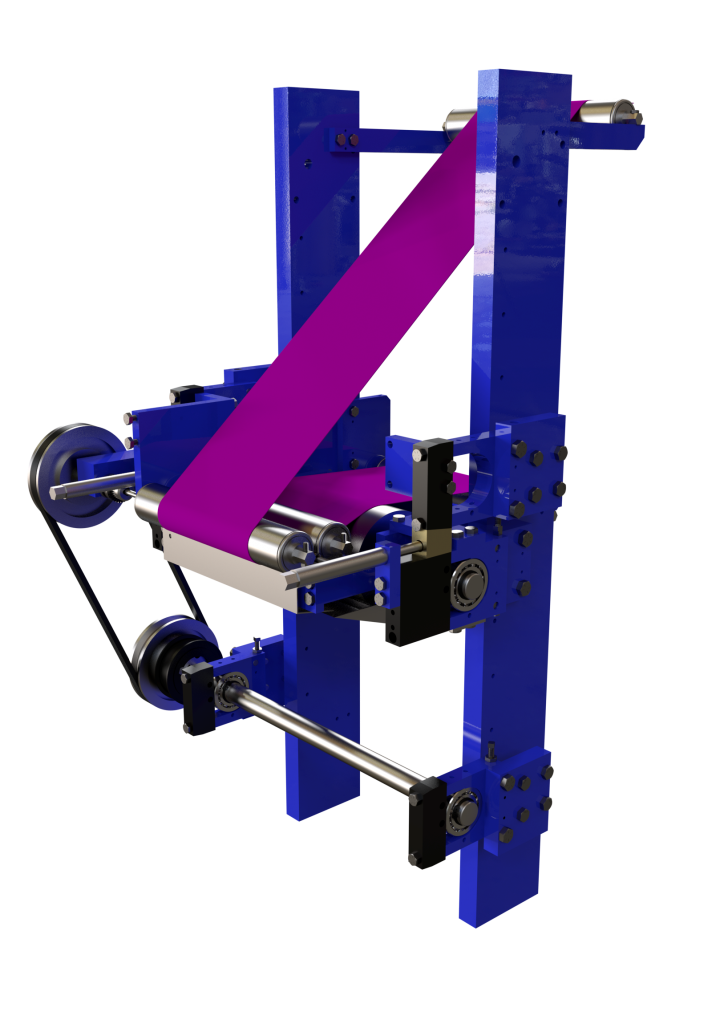

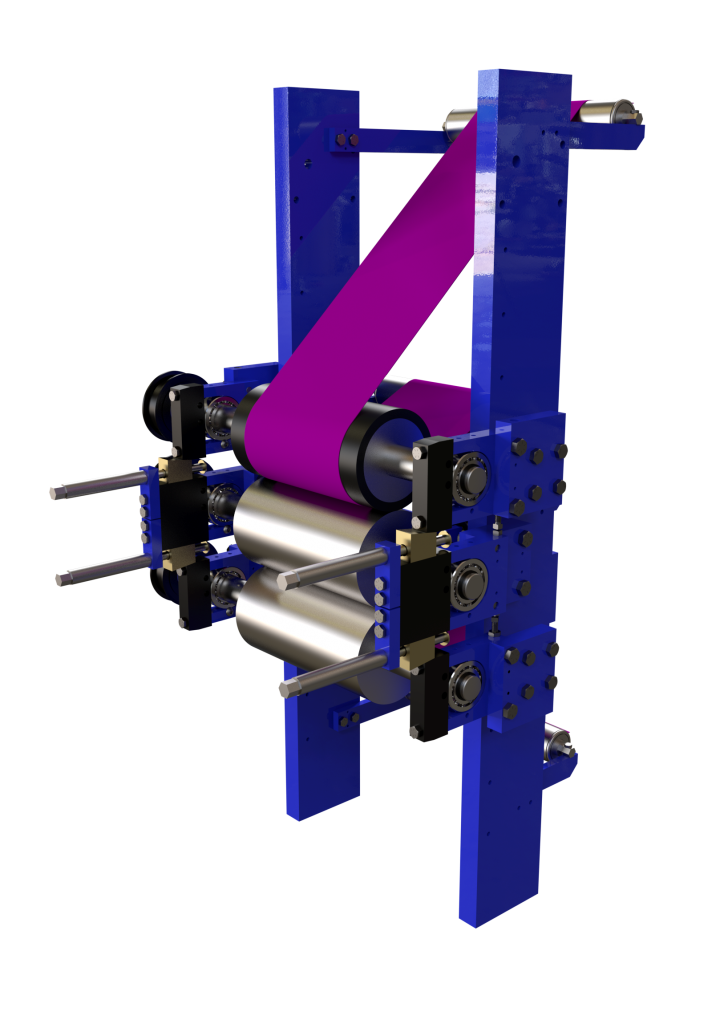

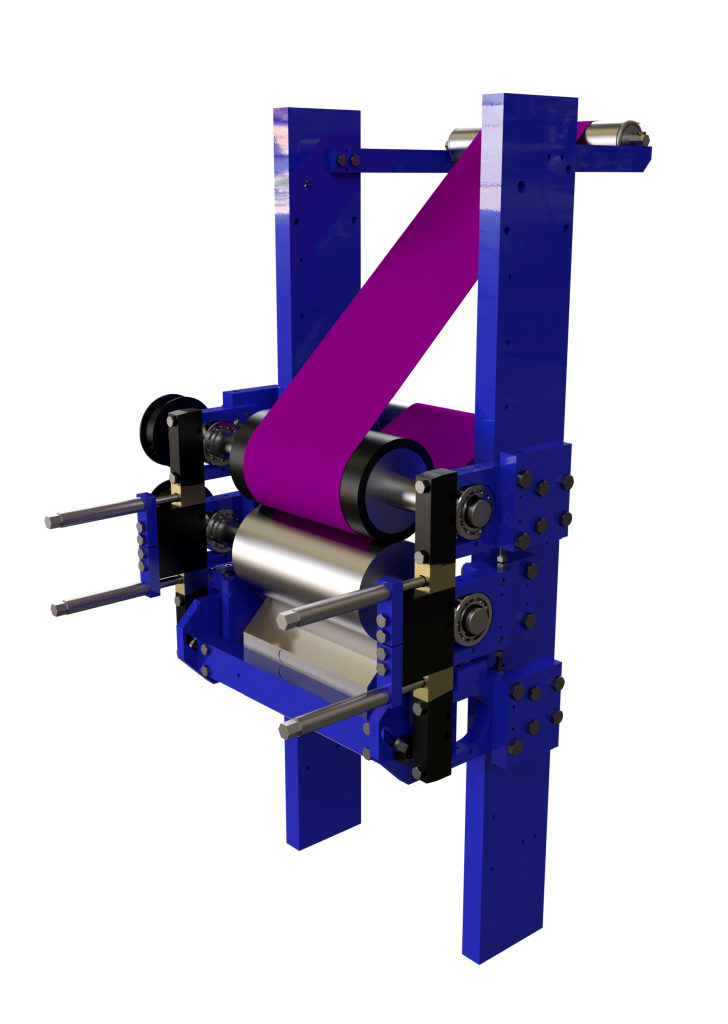

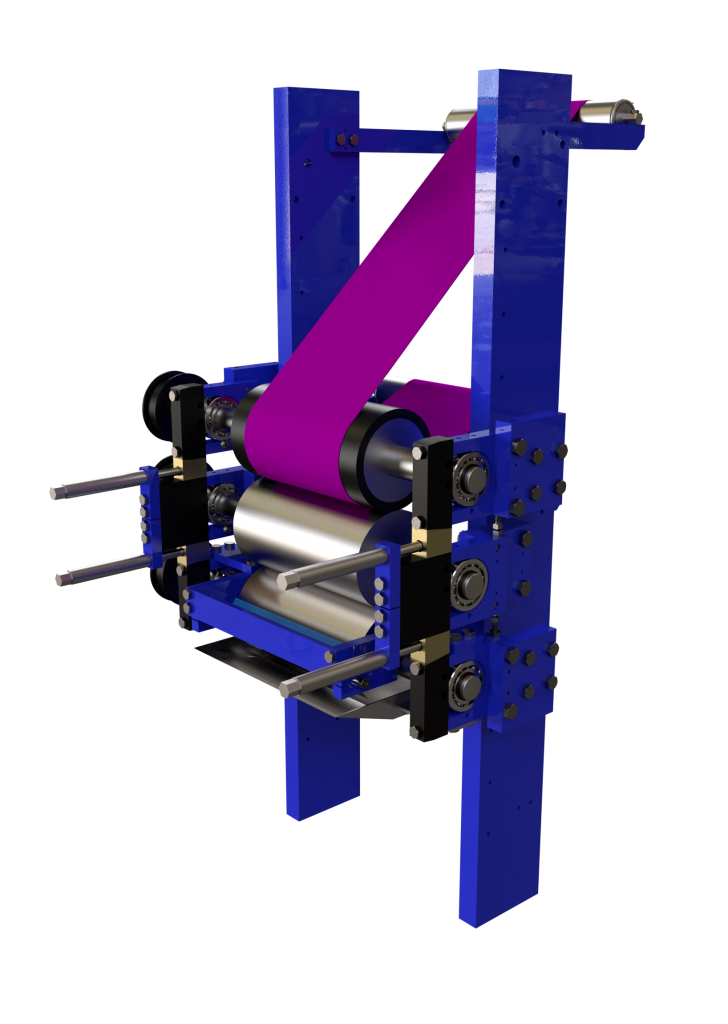

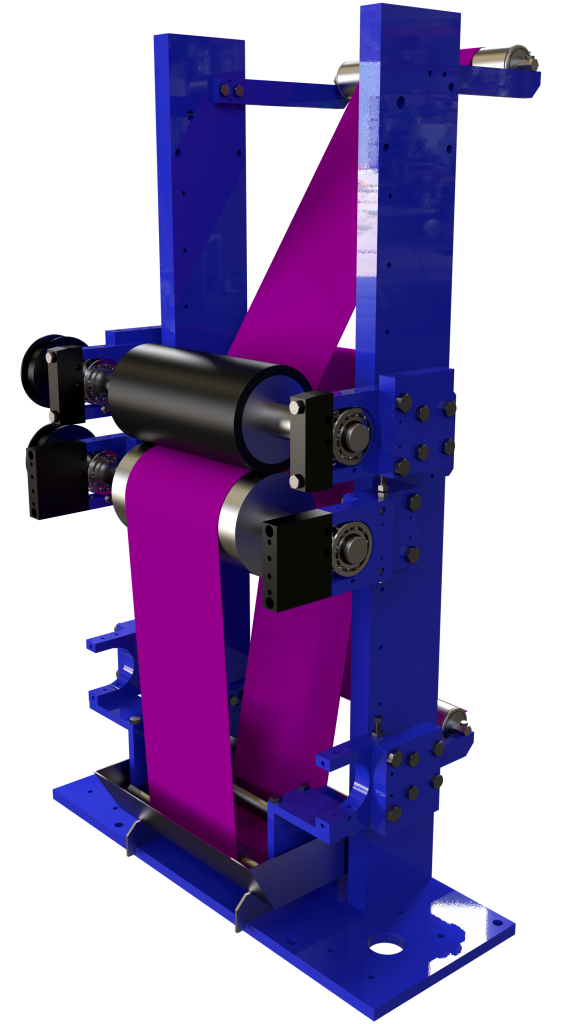

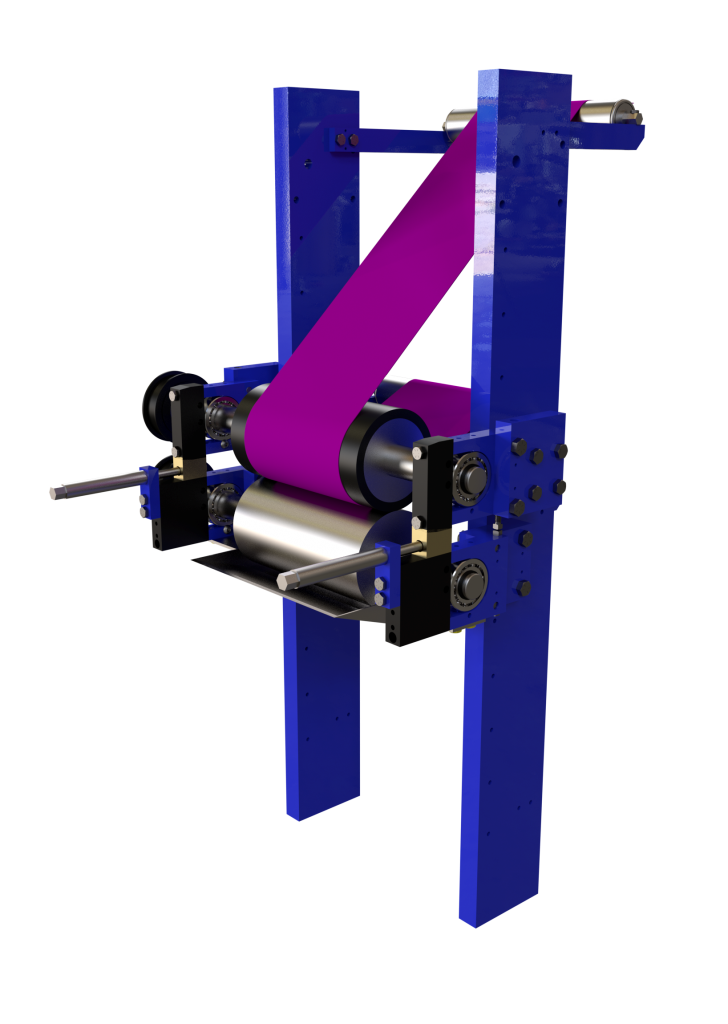

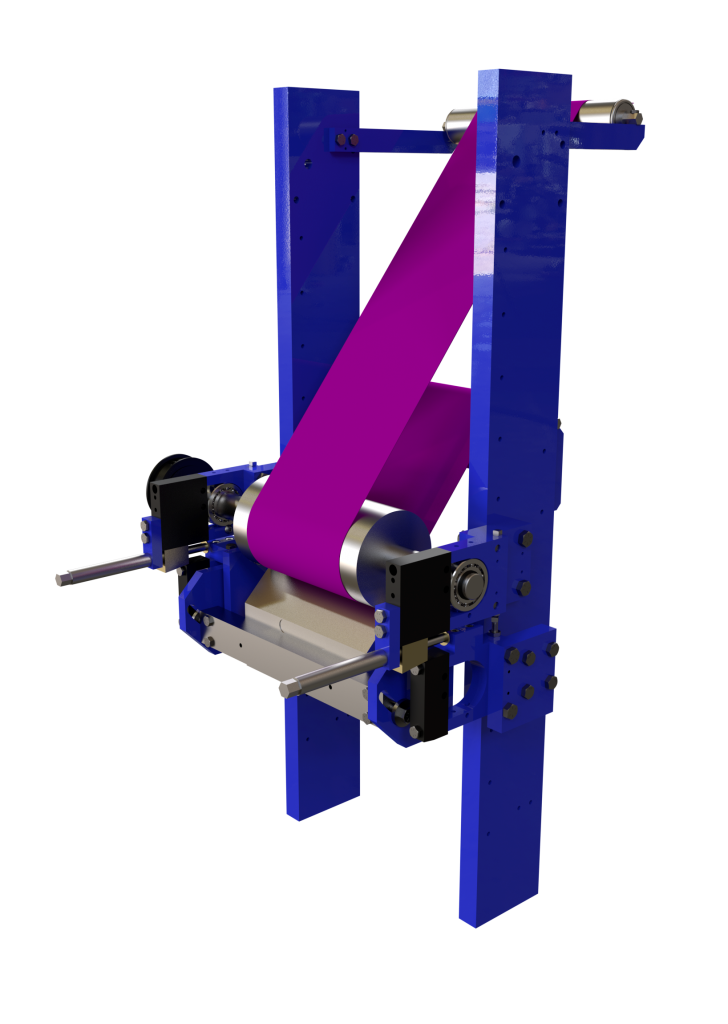

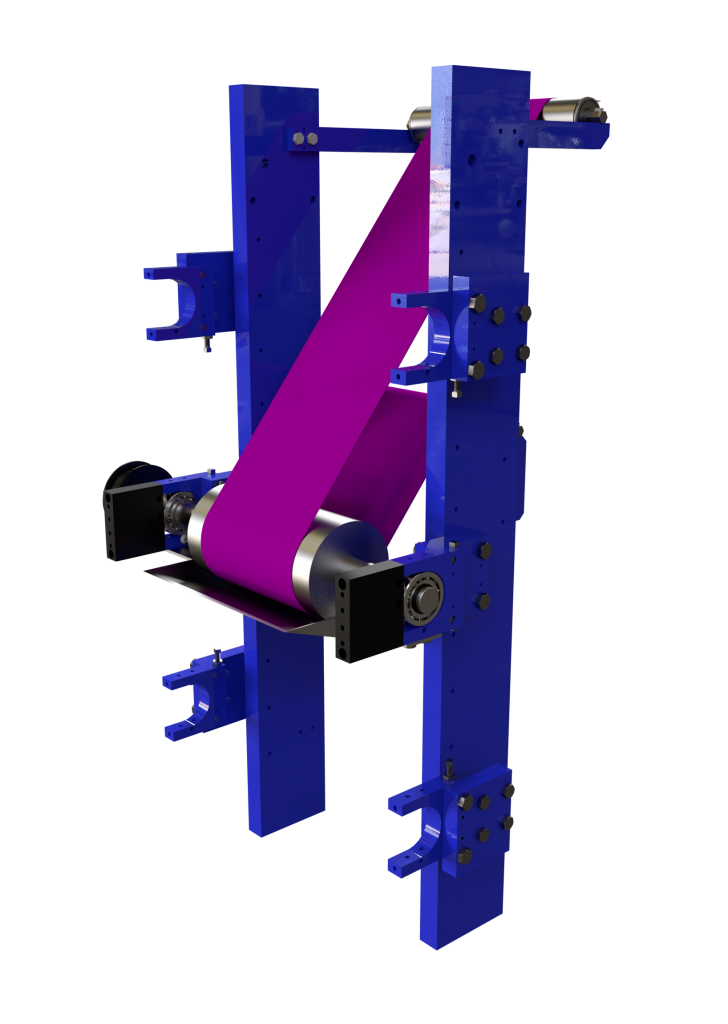

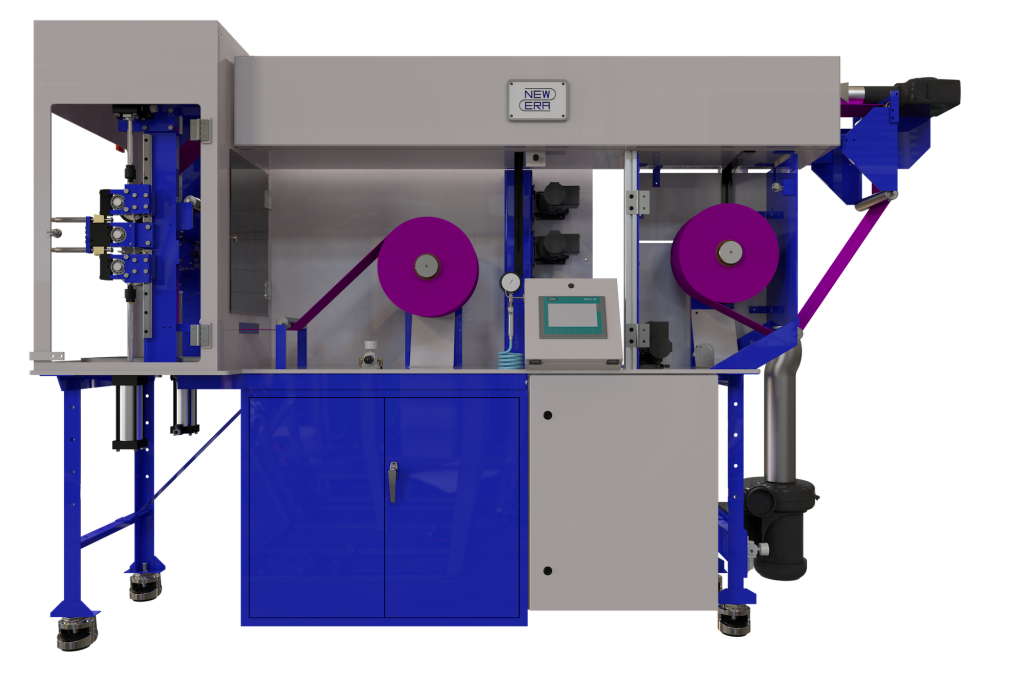

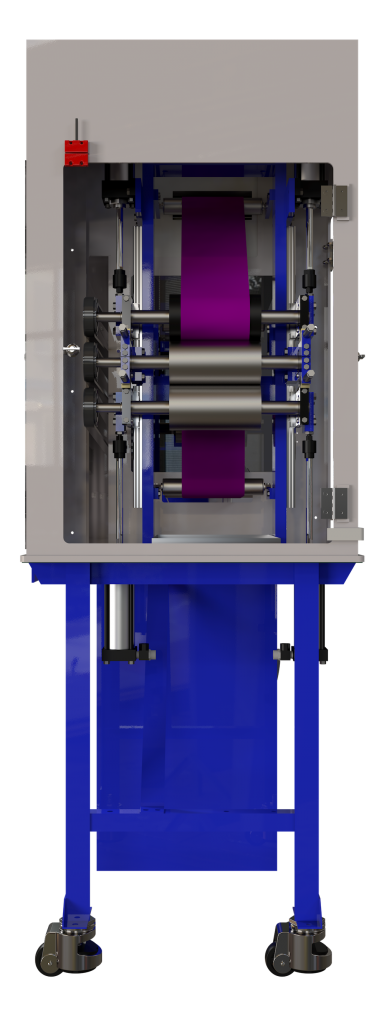

New Era’s NEW Portable Coating Line (PCL) is designed to meet a user’s ever-changing requirements in R&D, product development & product feasibility. The system offers maximum flexibility with a multitude of available coating application options as well as lamination capability. It is designed with true “table top” portability and ease of installation in mind.

The system, showcased at the ICE USA show, includes enhanced features such as:

-

Mayer Rod -

Nip Fed -

Offset Die -

Offset Gravure -

Saturation -

Squeeze

-

Die -

Dip -

Kiss -

Gravure -

Knife-over-Roll

- Web widths up to 6″

- Speeds of up to 50 FPM

- Unwind and Winder rolls up to 13″ diameter on 3″ cores

- Solvent and water base coating capability

- Fully enclosed coater assembly for use with solvents

- Multiple, interchangeable coating methods including:

- Kiss Coating

- Dip Coating

- Saturation Coating

- Squeeze Coating

- Mayer Rod Coating

- Gravure Coating (direct and reverse)

- Offset Gravure Coating (direct and reverse)

- Knife Over Roll Coating

- Reverse Roll Coating

- Die Coating (with coating supply system)

- Offset Die Coating (with coating supply system)

- Hot air dryer with adjustable air temperature

- Dryer and coater enclosure exhaust fan

- Touchscreen controls

- Minimal installation requirements:

- Mounted on wheels for ease of transportation

- Fits through a standard 30″ wide X 80″ high doorway

- Runs on 110 V power and 80 PSI air

- Plugs into standard wall outlets

- Single point compressed air connection

- Single point exhaust ducting

- Units with single coating method available for under $90,000

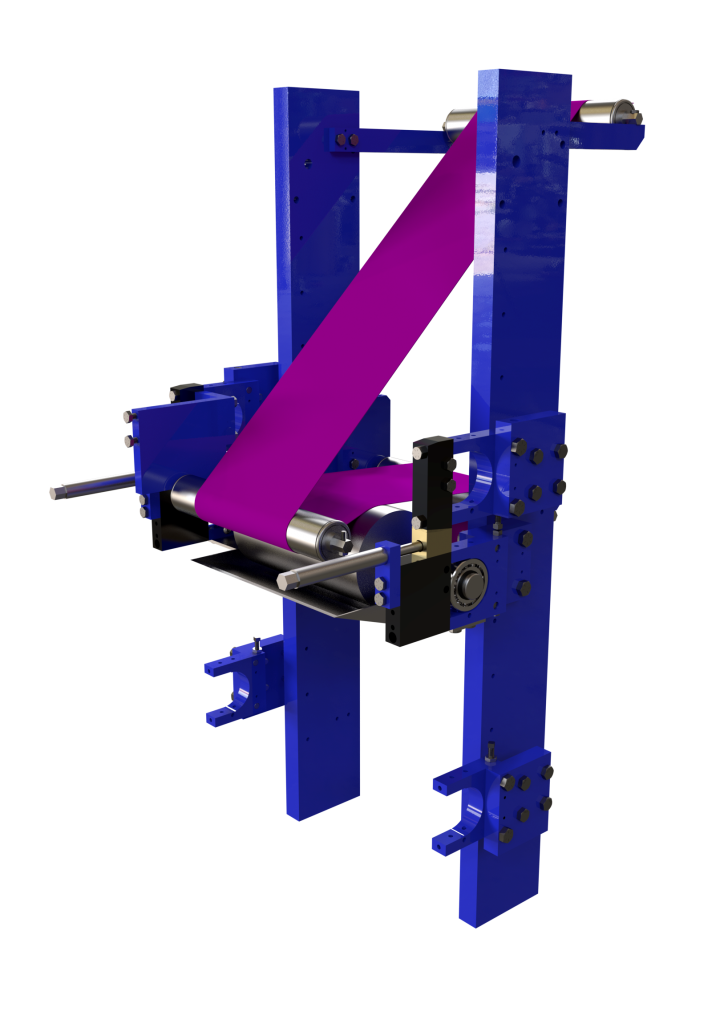

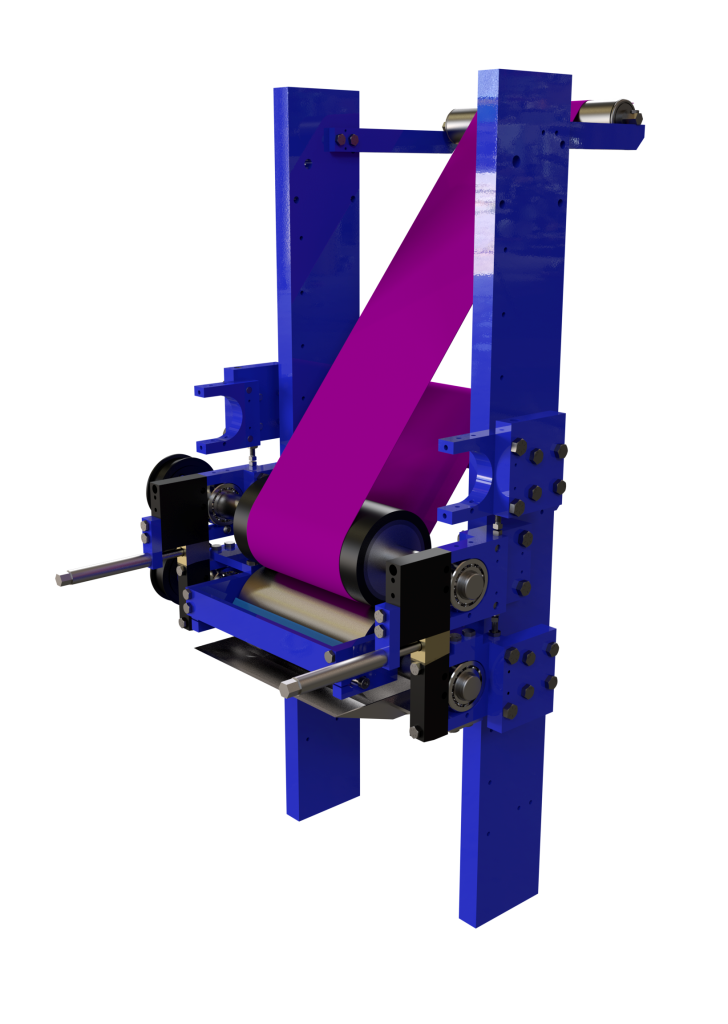

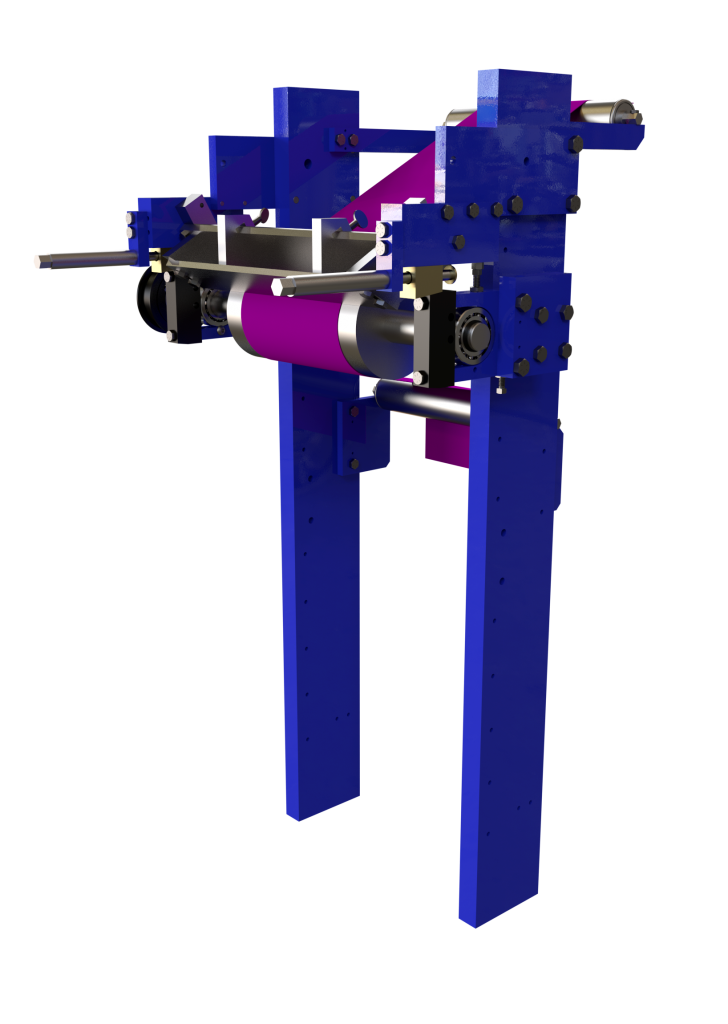

- Lamination (unwind and nip) can be added to any coating system for under $15,000

- Complete systems, including all of the above outlined coating methods and lamination, available for under $160,000

Downloadable Brochures in PDF Format

Downloadable Brochures in PDF Format