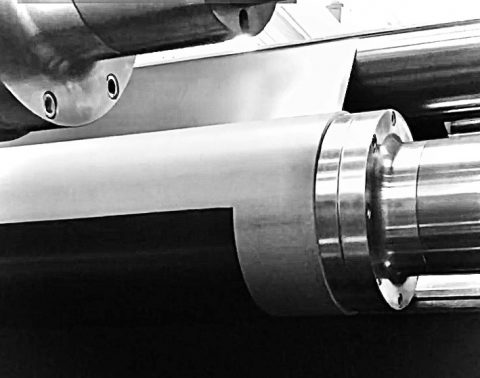

New Era’s patented Carousel turret winding system was designed specifically for products which cannot tolerate any fold-back, wrinkles or imperfections at the core. As this winder has penetrated more market segments, we have found that it is also uniquely suited for cast or tentered film production lines in that it provides a means to safely and effectively begin winding on a new core without stopping the web or using an accumulator. The marriage of these important qualities separates the Carousel from other automatic winding systems in the industry, and positions it well for the film winding marketplace.

Many products can have significant scrap generated when imperfections at the core start “show through” to each successive wrap of material, and the Carousel Winder addresses this. Not only can the Carousel Winder eliminate these imperfections at core start, but it can hit a single strip of double-sided tape on the core, thereby avoiding product losses associated with a spiral wrapped core. Our patented system utilizes a traversing blade at full line speed, without the use of an accumulator. The design of the winder transfer mechanism eliminates the bias cut typically associated with traversing cutoff blades by having the blade travel at match line speed with the web. This enables the Carousel Winder to provide a straight, clean cut leading edge of material to the core at full line speed.

This winding system is ideal for clean room environments, high value products and sensitive web materials which can be damaged by any imperfection at core start. All of New Era’s turret winders are provided with automatic tension control, diameter calculation, and can also incorporate features such as shaft-less chucking of varying web widths, lay-on roll or gap winding, automatic guiding, built in tension isolation pull rolls and tool-less changeover of winding modes.

Downloadable Brochures in PDF Format

Downloadable Brochures in PDF Format