Lamination System Application and Design Considerations – Part 3 of 4

The following is the third part in a series of 4 blogs that will go through a white paper written by New Era Converting Machinery’s

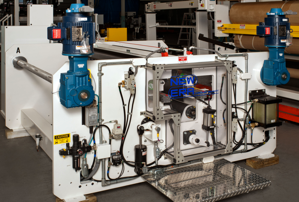

Coating, Laminating and Embossing Systems for a wide range of Industries and Products

Unwind Systems with Automatic Tension Control, Guiding and a Range of Chucking Options

Winding Systems with Automatic Tension Control, Guiding and a Range of Chucking Options

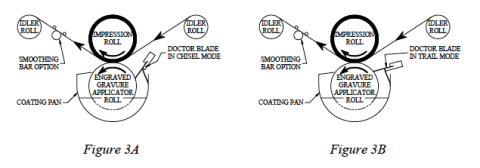

A Variety of Hot Melt, Water & Solvent Based Web Coating Station options for both Dedicated Coating or Modular Systems

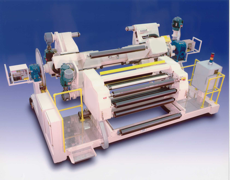

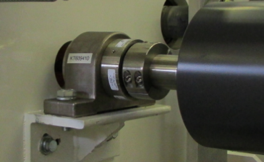

High and Low Pressure Nip Sets for Combining or Calipering a Range of Materials

Web Conveyance Equipment Including Pull Rolls, Heating & Cooling Stands, Flips and Turns

Narrow web Coating, Laminating & Embossing Equipment for Pilot Scale or Production Environments

Fully Integrated Web Drying Systems for a variety of Web Coating Applications

Specialty Equipment and Ancillary Systems for Web Handling and Converting Systems

The following is the third part in a series of 4 blogs that will go through a white paper written by New Era Converting Machinery’s

The following is the second part in a series of 4 blogs that will go through a white paper written by New Era Converting Machinery’s

The following is the first part in a series of 4 blogs that will go through a white paper written by New Era Converting Machinery’s

The following is the third and final part in a series of 3 blogs that has gone through a white paper written by New Era

The following is part two of a series of 3 blogs that will go through a white paper written by New Era Converting Machinery’s John A.

The following is part one of a series of 3 blogs that will go through a white paper written by New Era Converting Machinery’s John

The following is the third and final segment in a series of 3 blogs that have gone through a white paper written by New Era

The following is part two of a series of 3 blogs that will go through a white paper written by New Era Converting Machinery’s Bob

The following is part one of a series of 3 blogs that will go through a white paper written by New Era Converting Machinery’s Bob

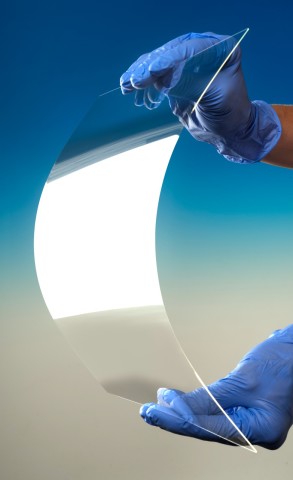

Paterson, NJ (July 28, 2015) . . . What began as a conceptual idea several years ago between a known leader in the glass industry

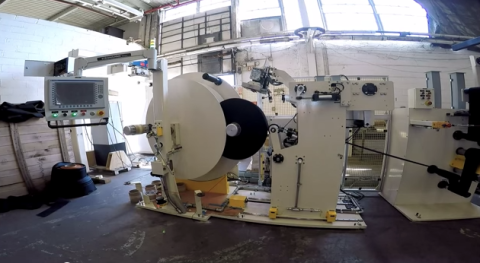

This video shows a narrow width, cantilevered turret winder making a transfer at full production speed (in this case 300 fpm) utilizing a shear type

The following is the third and final part of a series of 3 blogs that will go through a white paper written by New Era

The following is part two of a series of 3 blogs that will go through a white paper written by New Era Converting Machinery’s Bob

The following is part one of a series of 3 blogs that will go through a white paper written by New Era Converting Machinery’s Bob

The following is the third and final part of a series of 3 blogs that will go through a white paper written by New Era